Traditional and Contemporary Drying Methods an Overview

DOI:

https://doi.org/10.21760/jaims.9.6.16Keywords:

Ayurvedic, Bhanu Paka, Atapa Suska, Chaya Suska, Pharmaceutical, Drying, DryersAbstract

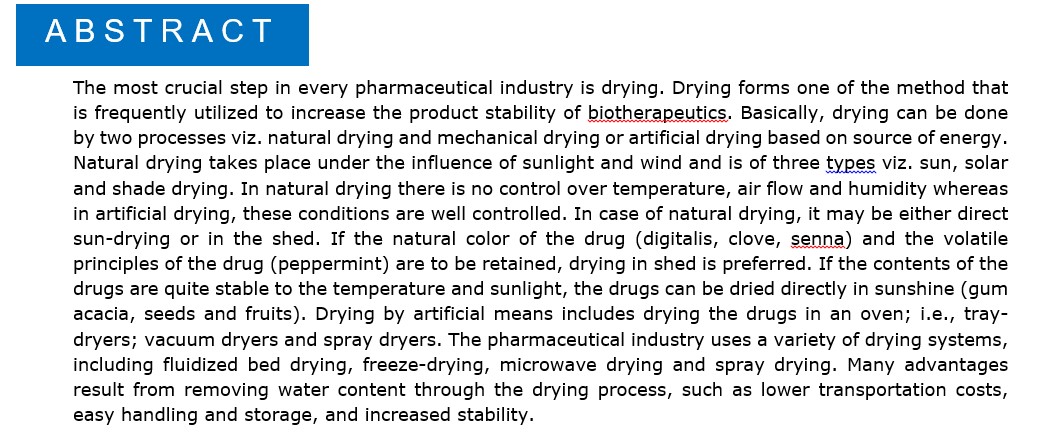

The most crucial step in every pharmaceutical industry is drying. Drying forms one of the method that is frequently utilized to increase the product stability of biotherapeutics. Basically, drying can be done by two processes viz. natural drying and mechanical drying or artificial drying based on source of energy. Natural drying takes place under the influence of sunlight and wind and is of three types viz. sun, solar and shade drying. In natural drying there is no control over temperature, air flow and humidity whereas in artificial drying, these conditions are well controlled. In case of natural drying, it may be either direct sun-drying or in the shed. If the natural color of the drug (digitalis, clove, senna) and the volatile principles of the drug (peppermint) are to be retained, drying in shed is preferred. If the contents of the drugs are quite stable to the temperature and sunlight, the drugs can be dried directly in sunshine (gum acacia, seeds and fruits). Drying by artificial means includes drying the drugs in an oven; i.e., tray-dryers; vacuum dryers and spray dryers. The pharmaceutical industry uses a variety of drying systems, including fluidized bed drying, freeze-drying, microwave drying and spray drying. Many advantages result from removing water content through the drying process, such as lower transportation costs, easy handling and storage, and increased stability.

Downloads

References

Brahmananda Tripathi, Saranghadhara-Samhita of Pandita Sarangadharacarya, Varanasi; Chaukhambha Orientalia publishers; 2022. 12p.

Brahmananda Tripathi, Saranghadhara-Samhita of Pandita Sarangadharacarya, Varanasi; Chaukhambha Orientalia publishers; 2022. 14p.

Ras Vaidya Nagindas Chhaganlal Shah, Bharat Bhaishajya Ratnakar part vol-1, Published by Narendra Prakash Jain, Motilal Banarsidas, Delhi 7 and printed by Shantilal Jain, Shri Jainendra Press, A-45, Phase-1, Naraina, New Delhi 28, page no. 29,35-36,159,167.

Rasvaidya Nagindas Chhaganlal Shah, Bharat Bhaishajya Ratnakar part vol-3, Published by Narendra Prakash Jain, Motilal Banarsidas, Delhi 7 and printed by Shantilal Jain, Shri Jainendra Press, A-45, Phase-1, Naraina, New Delhi 28, page no.176,317,631632.

Vilas Dole, Dr. Prakash Paranjpe, a text book of Rasashastra, Chaukhambha Orientalia publishers; New Delhi;2021. 305p

Grant Thamkaew et al. A review of drying methods for improving the quality of dried herbs, CRITICAL REVIEWS IN FOOD SCIENCE AND NUTRITION;2021, VOL.61, NO.11, 1763-1786

Arunima Mukherjee et al. Standardization of drying technique for the production of powder from Shankhpushpi leaves The Pharma Innovation Journal 2021; 10(6): 13-16

Kulshrestha Mayank Krishna et al. EFFECT OF DIFFERENT DRYING METHODS ON THE QUALITY OF STEM BARK OF TERMINALIA ARJUNA ROXB, IJRAP 3(4), Jul - Aug 2012

Ashok k. Gupta, Introduction to Pharmaceutics-1 3rd edition, CBS Publishers & distributors;1994. 192p-202p

K. rami chandra Reddy, Bhaishajya Kalpana vijnanam, Chaukhambha sanskrit bhaan ed-2020, sanskrit, Ayurveda & Indological publishers & distributors. Page no 218

Renjini A. S et al. Ijppr.Human, 2022; Vol. 23 (4): 93-108.

Pharmaceutical Science in Ayurveda - Subhose et al.

https://www.yamato-sanko.co.jp/english/products/tunnel_dryer/12-04-2024 time12:14

https://www.kerone.com/tunnel-dryer.php 12-04-2024 time 12:00

https://www.processingmagazine.com/material-handling-dry-wet/powder-bulk-solids/article/53042431/introduction-to-rotary-dryers 12-04-2024 time 12:30

https://www.lodhapharma.com/fluid-bed-dryer-importance-in-pharma-industry.php 12-04-2024 time 12:45

https://www.simplepharmanotes.com/2022/01/vacuum-dryer.html 12-04-2024 time 01:00

https://www.researchgate.net/publication/265314817

https://www.pharmacy180.com/article/drying-of-crude-drugs-44 12-04-2024 time 1:30

A.S. Mujumdar, Handbook of Industrial Drying, Fourth Edition (pp.689-712) Edition: 1Chapter: 29Publisher: CRC Press